Latest technology and innovation keeping ahead in cable tray systemsWho is Zip Cable Tray Systems Inc.?Zip Cable Tray Systems Inc. was designed in 1994 at the specific request of the telecom industry for a lightweight cable tray system that was strong, yet fast and easy to install. Recently rebranded as Zip Cable Tray Systems Inc., the new name better reflects our superior product design and service that our company has offered for over 2 decades. Our mission here at Zip Cable Tray Systems Inc. is to continue providing our clients with the market-leading cable tray products and excellent customer service that our company has become known for. Made in Canada! Located in Pointe-Claire (Montreal), Quebec, Canada, our modern production facility is equipped to meet any special requirement you may have. Zip leads the industry when it comes to cable tray systems and wire management! Behind every meticulously handcrafted Zip cable tray and cable ladder are highly skilled employees who work in a state-of-the-art facility located less than an hour from the Canadian - U.S. border and 20 kilometers from downtown Montreal. A Canadian company leading the industry / in aluminum cable tray systems and wire management.

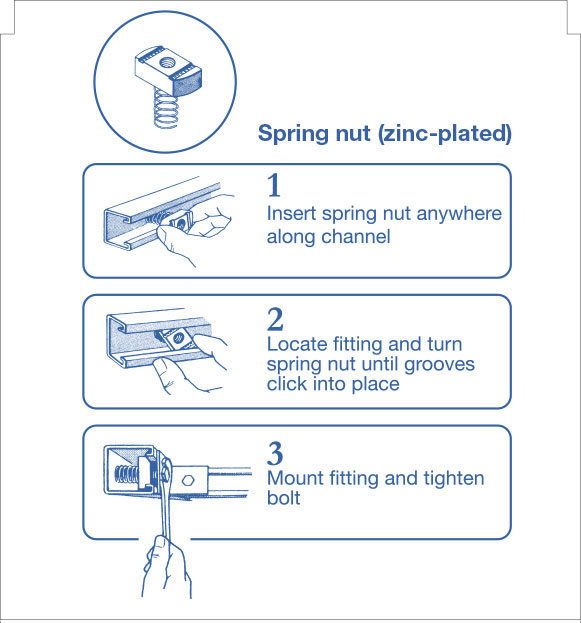

Zip Cable Tray / BenefitsFast Installation:One of the prime features of the Zip cable tray design is that the channel-style siderails accept spring nuts. This eliminates the need for any drilling and makes for an extremely fast and simple installation. Fast Delivery:90% of our orders ship in less than a week, a market leader! A large inventory of popular items (ladder-style cable racking) are in stock for immediate delivery. All-aluminum Construction:

Aluminum cable tray systems are clearly superior in construction and appearance to electrical raceway systems made from other metals. Zip has taken that benefit and incorporated the best product design to fully utilize the advantages of aluminium. Wire Management at its best with ZipThere is always a Zip cable tray and wire management solution to fit your needs. Whether you are doing telecom work or high voltage electrical wiring, routing 1 cable or 1000's of cables, multiple levels, branching off in many different directions, Zip cable trays and cable racks will get the job done right! We cater to many industries that all have special requirements. Our priority is to find a cable raceway solution for your specific situation. Whether it is the low profile cable tray (BT Series) or 6" high siderail with a sweeping 36" radius, we have a solution for your project! Zip's ladder-style cable tray is lightweight, durable and simple to install. With Zip cable tray and cable racking your wire management is in good hands. UL Classified / CSA ApprovedZip cable tray is classified by UL and CSA/NEMA tested and approved for use in Canada and USA and complies with the electrical codes of both countries (CEC and NEC). Powder coating with any colour is available, but note that adding a painted coating to the cable tray negates the UL and CSA/NEMA certification! Jumper cables will need to be installed across cable tray splices to maintain electrical continuity. Electrical ContinuityZip's cable tray systems couplings do not require additional equipment grounding conductor's (EGC), also known as 'jumper cables', across splices. This is a significant cost saving. In accordance with the harmonised CSA/NEMA cable tray standard, a strict electrical continuity test was performed on all Zip cable trays. This test measures the electrical resistance across a splice and the result must be less than 0.00033 ohms! All Zip cable trays easily passed the electrical continuity test. Some clients create their own, much stricter standards. For example, in order to qualify for the Motorola R56 standard, jumper cable across each splice is a necessity. Zip has succeeded in satisfying many industries:

If you need more information about our products or support, you can contact our cable tray and ladder racking specialists. Ask for our latest brochure or catalogue which has all part numbers and list prices shown for easy reference. |